Reverse Engineering Service

Transform Physical Products into Accurate 3D Models and CAD Files

What is Reverse Engineering?

Reverse engineering is the process of analyzing and reconstructing physical parts into digital 3D models or CAD files for redesign, replication, or improvement.

It’s ideal for replacing obsolete parts, improving product designs, and analyzing competitor components.

It’s ideal for replacing obsolete parts, improving product designs, and analyzing competitor components.

Key Benefits

Recreate parts without original design files

Ideal for legacy or discontinued components

Generate accurate CAD models for re-manufacturing

Improve or modify existing designs

Faster product development and prototyping

Supports 3D printing and CNC manufacturing

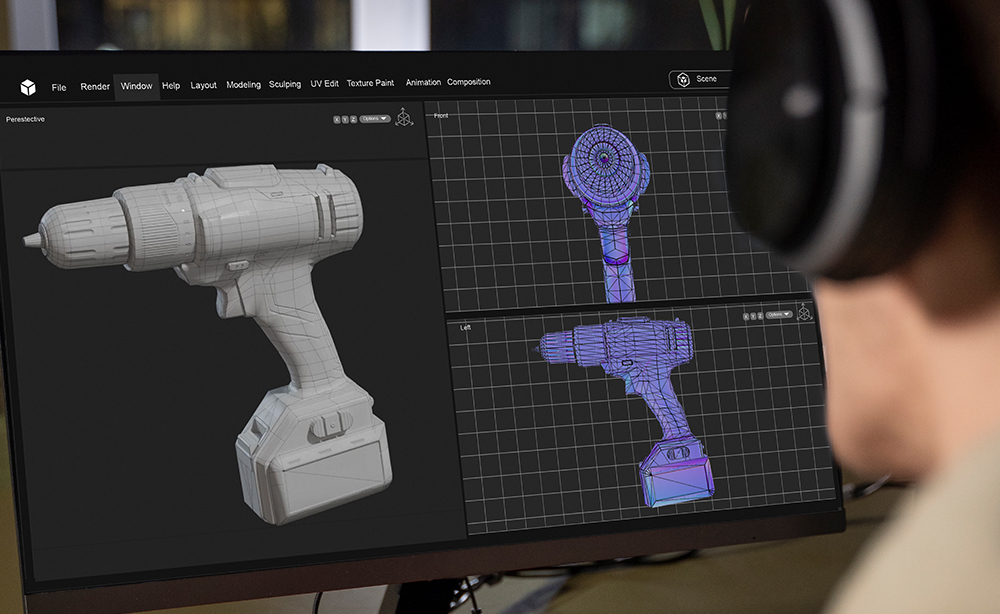

How It Works

1

The physical part is scanned using 3D scanning technology

2

The scan data is processed and converted into a mesh model

3

Our engineers create a precise CAD model (STEP/IGES/etc.)

4

Final files are delivered and ready for production or redesign

5

In addition part improvement or optimization recommendations

Our advanced facilities and expertise support a variety of technical specifications and manufacturing capabilities, tailored to achieve the highest quality results.

Accuracy: up to ±0.05 mm

Support for parametric modeling

We proudly serve a wide range of industries, supporting their needs with innovative prototyping and manufacturing solutions.

Automotive and machinery

Consumer electronics

Aerospace and defense Industrial manufacturing

Medical devices

We offer a wide range of materials to meet diverse project requirements, ensuring the perfect match for your design, functionality, and performance goals.

3D CAD files (STEP, IGES, SolidWorks, etc.)

STL files for 3D printing

2D technical drawings (if needed)

Get a Reverse Engineering Quote

Tell us about your project needs, and our team will provide you with a tailored quote. Let’s bring your ideas to life efficiently and accurately.

Frequently asked questions

What if I don’t have any design files for my part?

No problem! That’s exactly what reverse engineering is for—we recreate the design from the physical part.

Can you reverse engineer broken or damaged components?

Yes, we can often reconstruct missing or damaged sections digitally before creating a full model.

How long does the process take?

It typically takes 3–7 business days depending on part complexity and required outputs.

Can the reverse-engineered model be used for CNC machining or 3D printing?

Absolutely. We ensure the final files are compatible with manufacturing methods like CNC, injection molding, or 3D printing.